How do I Sharpen Swords?

How do I Sharpen Swords?

And Info on "Live Steel"

How do I Sharpen Swords?

How do I Sharpen Swords?

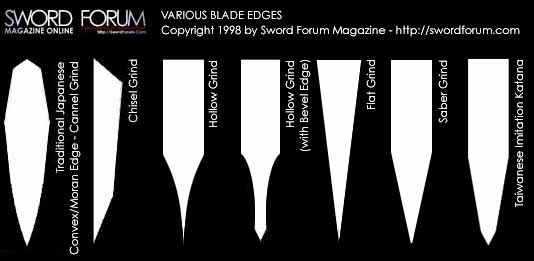

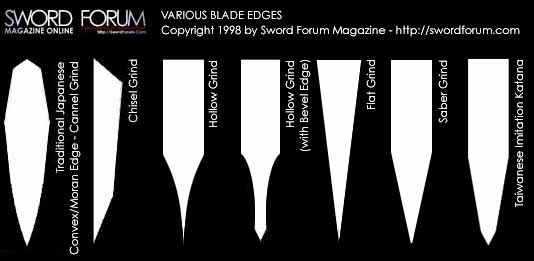

The previous image and following text is taken from the Sword Forum Magazine Online posting area. Please feel free to go there, and ask questions about anything yourself. The first section is written by "Warangel" himself, and is of such value that I feel it must be shared with the rest of the sword loving world. The picture and text is used by written permission and is copyrighted by Sword Forum Magazine Online. Thank you WarAngel!

"This is not a simple question, as the swords on the market are so varied. Each has a different shape and is made with a different purpose."

"You'd have to be careful with Marto. Some of the Taiwanese swords have a beveled edge, which can be reinforced with a diamond hone file. However, the Marto katanas don't necessarily have a beveled edge like the illustration for the Taiwanese Imitation Katana (far right). The Marto "Sword of the Dragon" is more a saber grind. Sharpening it on a grinding wheel even at low speeds would scratch the heck out of the sword, and so would a diamond hone file. You'd have to buff it back to shape. In short, it's not worth the trouble; the sword was tempered in such a way that those Marto swords will not hold an edge after a few serious cuts of cardboard."

"The Taiwanese junk are actually tempered a little higher on the Rockwell hardness scale - that's my hunch. They tend to use 440. 440 with a higher hardness will probably give you a better edge, but again, these weren't made to be serviceable weapons though many sales catalogs give people that impression."

"Using a grinder at high speeds will ruin the heat treating of a sword, so this is not the case for a Paul Chen sword like a Shinto katana, Bamboo katana, Golden Oriole and Musashi Daito. But here, educating the prospective customer that Japanese swords were not made "razor sharp" and that "razor sharp" is just marketing jargon to inspire prospective buyers. The Japanese used their swords in a skilled cutting motion, and the cutting ability of a sword came from the ability of the swordsman. It is possible to polish the sword traditionally to give it a finer edge, but the cost will match or exceed the price of the Chen-made sword!"

"The CAS Iberia swords that are specifically made in the Philippines (ending with -PP). As opposed to Marto or Martespa, these Iberia swords are made of "high carbon spring steel". These weren't made as wallhangers per se. They're made as beaters, in as much as they can withstand being whacked around. They're not extremely beautiful. And if you put an edge on these swords, depending on the sword's geometry, you're not losing a lot scratching up a $150 sword. A diamond hone file would be fine with these babies. But keep in mind that our tests show that the thermal treatment to these swords are lacking, and they are tempered softer to take blows. They will probably fare equally or worse than the stainless steel stuff. We're finding that the Rockwell hardness is in the low to mid 40's for these swords. Conversely, Marto rates at 48-52. Some Taiwanese swords are upwards of that too."

"But, in short, special care should be given to Japanese swords. The Paul Chen swords are technically Japanese-*style*. But the owner should respect the sword nonetheless - and definitely more than just a stainless steel approximation of a katana."

"Traditionally speaking, the Japanese sharpened and polished in one single procedure. This was done because preserving the convex geometry of the blade edge and blade body was extremely important."

"The absolute wrong way is to use a knife sharpener - be it manual or mechanic - which only creates a bevel on the last millimeter or two of the edge, thereby destroying the blade geometry."

"The other absolute wrong way is to use a grinder, as the heat buildup from the friction would ruin the temper."

"The Paul Chen swords really throw all this on a curve, because it's the first time a sword was so darn affordable. The World War II guntos could theoretically be picked up at the same price range, but giving them the same kind of restorative polish as you would with 400 year old antiques isn't worth it, because the cost of the polish would exceed the value of the sword!"

"Let's establish something first. Can you live with a sword that is not "razor sharp"? Because Japanese swords were not "razor sharp" to begin with. Much of the cutting ability comes from the ability of the swordsman. If the edge is formed too thin, it will satisfy your "razor sharpness" requirement, but the edge will be prone to breakage, and you'd be left with a defective sword. That's why I always stress that swords don't always have to be "razor sharp" - in fact, much of that is plain marketing jargon in many mail-order catalogs to impress people."

Steve Talking Now - So what should you take from all this? Well, I would tend to leave things alone. If you must sharpen a blade, I would only do it to an Iberia blade, since these are at least meant to be swung around. The Marto and Martespa blades,... Well, leave them on the wall or in their stand, and if someone wants to look at it, pull it out and let them go, "Ooh, ah!", but don't try to impress them by cutting a two by four in half.

Which brings me to the second part of this particular page. If you insist on hacking things with your sword, please don't complain when it starts looking really beat up. Whenever you hit any two objects together, there will be some deformation of both objects (hopefully the target will deform more than the sword). This is basic physics. What ends up happening with swords is that the edge starts deforming more and more as time passes, until the whole blade become unusable. If the "burrs" are ground out, you start thinning the blade (and getting into the softer portion of the blade once the original edge is gone) until it finally breaks. The movies would have you believe that a sword could be used constantly for 500 years, and be perfectly serviceable. That just isn't the case! If you have a 400 year old sword, then it has probably only seen one battle (if that) and then rested in a museum of family collection. Even with a "real" sword, this is a concern. In medieval times, a soldier's sword was considered more of a disposable item if it was actually used for war. The sword would get beat up, and once the soldier couldn't repair it himself, he took it to the smith to be melted down and forged into a new blade. Have you ever been to a museum where they display pieces that were actually used in combat? They look like junk! The really fancy, shiny ones were the "Dress" swords.

Well, that's my advice and opinion. Take it for what it's worth. I know it's really hard to resist the temptation to swing it around and try to cut something (speaking from personal experience here). If you must, be careful! Swinging a sword around for Martial Arts Katas is acceptable, and any well made sword will stand up to that, but as soon as you hit something, all bets are off. If you want more information, go to the Sword Forum Magazine Online and ask them. These people are experts, I'm just a guy who loves swords.